Collaboration Facility

INNOVATION PRECINCT 1

- 3D Printing and Scanning

- Augmented Reality / Virtual Reality

- Collaboration Project Space

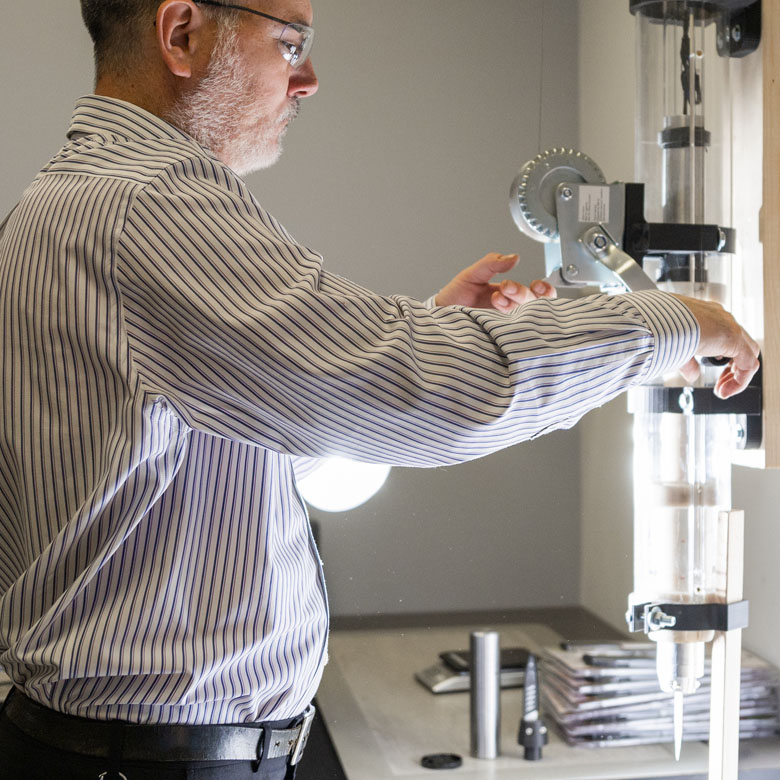

Impact Research Facility (SIRF)

1652 INNOVATION DRIVE

- Ballistic Testing

- Blast Testing

- Penetration Testing

Airborne Sensing Laboratory

Coming soon