Our Equipment

Ballistic Testing

Our facility can meet your need for speed in simulating challenges for protective materials, including vehicle, body armour, helmets (sports and military), and a variety of other applications.

The research range is used for testing protective equipment and clothing against ballistic threats.

The research range is used for testing protective equipment and clothing against ballistic threats.

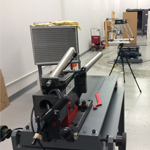

This BTTR and BLSH are used to evaluate injury potential and impact severity from behind armour blunt trauma and the protection performance and deformation testing of helmets.

This BTTR and BLSH are used to evaluate injury potential and impact severity from behind armour blunt trauma and the protection performance and deformation testing of helmets.

Blast Testing

We offer multipurpose blast simulation testing, from under vehicle improvised explosive devices to aircraft and hard landing seat impacts.

The blast simulator allows for studying the physical effects of injuries sustained during a blast event, tests parameters and fixtures to reduce the incidence of these injuries and vehicle configurations to absorb or reduce the effects of a blast.

The blast simulator allows for studying the physical effects of injuries sustained during a blast event, tests parameters and fixtures to reduce the incidence of these injuries and vehicle configurations to absorb or reduce the effects of a blast.

The three ton, custom-designed blast rig is the only equipment of its kind available to university sector researchers and private

and public sector organizations. At approximately 1/3 of maximum power, the simulator accelerates a 10 kilogram titanium piston to over 1,000G. The piston is driven by compressed gas breaking a shear pin to release the piston. Blast force simulation is easily controlled by choice of shear pin diameter and material. Effects are observed via high-speed camera and on-board instrumentation.

The impact rig is adaptable to any configuration dependent on the partners requirements.

Penetration Testing

The UBC STAR drop tower was custom designed and certified to meet NIJ standards. With up to 4.5 metres of drop length, the UBC STAR drop tower can achieve a velocity of up to 9 m/s, and with the

NIJ-style sabot, it delivers an impact of approximately 80 Joules of energy.

The UBC STAR drop tower is primarily designed around the NIJ 0.115.00 standard, and designed to hold the specified S1, P1, and spikes listed for this standard. The sabot can be easily refitted with a heavier mass and/or any shape or type of impactor, such as a ceramic paring knife. It is adaptable to meet future needs in a variety of impact testing scenarios.

The UBC STAR drop tower is primarily designed around the NIJ 0.115.00 standard, and designed to hold the specified S1, P1, and spikes listed for this standard. The sabot can be easily refitted with a heavier mass and/or any shape or type of impactor, such as a ceramic paring knife. It is adaptable to meet future needs in a variety of impact testing scenarios.